Why this law matters

Germany’s Single-Use Plastics Fund Act (Einwegkunststofffondsgesetz, EWKFondsG) turns environmental responsibility into a concrete, auditable obligation. If you first place certain single-use plastic products on the German market, you must register, report annual quantities, and pay into a central fund that finances litter-cleanup and awareness measures. Non-compliance leads to administrative fines, late-payment interest, reputational damage, and disrupted supply chains (e.g., retailers refusing non-compliant stock). In short: getting this right is both a legal requirement and a brand-protection move.

What the Act requires—at a glance

Who is in scope:

Typically manufacturers and importers (the first entity to place covered products on the German market). Distributors may be affected contractually or if they act as first placers in practice.

What products are in scope:

Selected single-use plastic items and composite products (plastic plus other materials) similar to those targeted by the EU SUP Directive—g., to-go cups, certain food containers, carrier bags, cutlery/straws/stirrers, and other commonly littered items.

Core obligations:

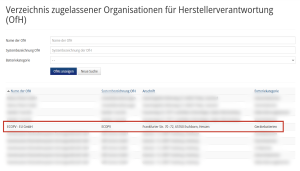

1)Register with the designated authority/portal before placing products on the market.

2)Report annual placed-on-market volumes by product category.

3)Pay the corresponding levy to the fund.

4)Keep records to substantiate the data you reported.

Enforcement:

Fines, late-payment surcharges, possible sales disruptions, and increased scrutiny in audits if you miss filings or under-report.

Note: Exact product lists, rates, and timelines are set by regulation and may be updated. Build processes that can adapt.

The most common compliance mistakes (and how to avoid them)

Mistake 1: Misclassifying the product scope

What goes wrong:

- Companies assume their items are “not plastic” because they’re paper-based, overlooking plastic coatings, lids, windows, or linings.

- Composite items are treated as exempt because plastic is “only a small part.”

- “Reusable-like” packaging is counted as reusable without meeting the formal reusability criteria (design, number of cycles, return system, etc.).

Fix it:

- Inquiry EPR service provider/agent about the correct category for your products

- Validate any reusable classification with written technical criteria and evidence.

Mistake 2: Incomplete or inaccurate quantity reporting

What goes wrong:

- Under-reporting due ignoring bundled components (e.g., cups + lids + straws).

- Counting units shipped rather than units first placed on the German market.

- Using wrong UoM (items vs. kg)

Fix it:

- Reconcile ERP, customs/import, and sales datasets against placement events in Germany.

- Implement two-person checks and variance analysis (e.g., quarter-over-quarter, channel-by-channel).

Mistake 3: Missing the “first placer” responsibility in the supply chain

What goes wrong:

- Importers presume the overseas manufacturer is responsible.

- Private-label arrangements leave ambiguity: Is the brand owner or the contract packer/importer the first placer?

- No clauses in supplier agreements defining who reports what.

Fix it:

- Identify the legal first placer for each flow (direct import, EU cross-border, domestic contract packing).

- Insert contractual obligations: data sharing, evidence of registration, indemnities for non-compliance.

- Maintain counterparty attestations and spot-check them annually.

Mistake 4: Missing registration or filing/payment deadlines

What goes wrong:

- Teams assume registration can be done “later” and proceed to sell.

- Annual report and payment dates are not on a centralized compliance calendar.

- Responsibility is diffused; no one owns the deadline.

Fix it:

- Register before any placement on the German market.

- Maintain a single compliance calendar (with owner, due date, backup owner).

Add automated reminders and escalation rules (e.g., finance director alerted 14 days pre-deadline).

FAQs

Q: We sell paper cups with a thin plastic lining—are they in scope?

A: Likely yes, because the plastic component triggers coverage. Confirm via formal category definitions and document your reasoning.

Q: Our supplier says they registered. Are we safe?

A: Not automatically. If you are the first placer in Germany, you carry the obligation. Obtain proof of registration and define responsibilities contractually.

Q: We changed a lid from PP to paper with a plastic window. Do we need to update reports?

A: Yes. Material changes can affect category and reporting.

Conclusion: Compliance is a catalyst, not a cost center

EWKFondsG is more than a levy—it’s a design brief. Companies that treat it as a cross-functional initiative cut risk, reduce material costs, accelerate packaging innovation, and strengthen customer trust. Build the foundations now—clear ownership, clean data, strong contracts, and living documentation—and you’ll turn compliance from a last-minute scramble into a competitive advantage.